TROUBLESHOOTING METHODOLOGY

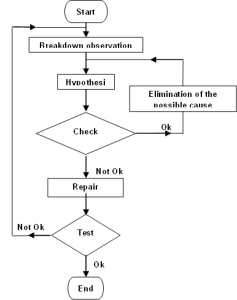

Reminder: To repair an installation, it is to recondition it operating. This imposes a lot of method and care. The search for one or several faults to eliminate the cause of the disturbances requires a logical progress in the progress of the work with the exception of any method creature of habit of repair by "stroke of luck"

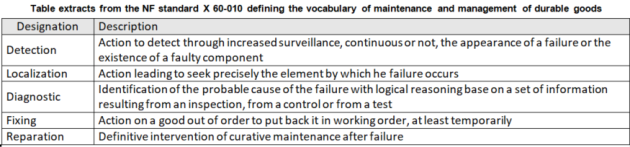

Definition :

Step 1: Search and location of the faults This stage can require the presence of voltage and, possibly, that of the other power sources if it exists there. In LV, it understands the diverse operations of measurement of the electric values not requiring the opening of circuits. Step 2: Elimination of one or several faults, repair or replacement of the defective element. This stage does not require the presence of voltage and must be made according to the modalities of the works switched off. Step 3: Settings and checks of the functioning of the equipment after repair. The intervention is ended, if the equipment works normally: - With control components assigned normally (pushbuttons, switches) - With the normal settings (limit switch, level, temperature) - If every devices of mechanical protection and electrical locking are in service. |

APPLICATIONS:

- Inform from the working voucher of the problem the top of documents 1 and 2 (report and process of intervention)

- Inform the frame "noticed faults" of the report of intervention (doc 1)

- Inform columns "issued assumptions" and "Tooling / Measuring tools used" of the process of intervention