5. Starting an asynchronous machine

5.1. Case of the starting torque

Method :

|  |

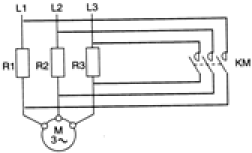

Method : Direct On Line (DoL)

Direct startup of an asynchronous machine causes a high starting current. Id = 6 to 8 In.

Make sure that the protections are not tripped: fuse use aM.

To avoid the disadvantage of the fuse aM (melting delay), the motor is protected against overloads by a thermal tripping device

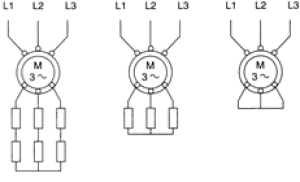

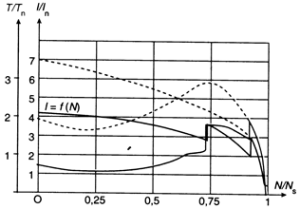

Method : Star – Delta Starting

This type of startup avoids the disadvantage of the strong current at startup. Indeed by using a reduced voltage at startup, the current is limited

|  |

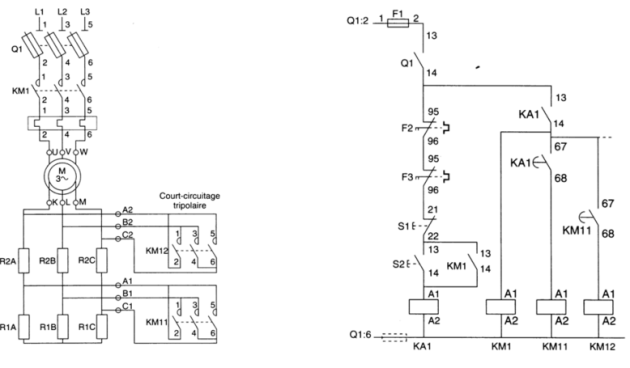

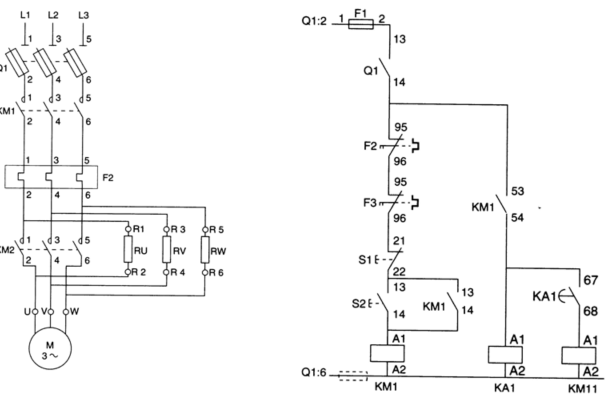

5.2. Stator Starter : Starting by eliminating Stator resistors

Always to eliminate the intensity peak at startup, work under reduced voltage. This reduced voltage is achieved by inserting stator resistors in series with the motor. We can achieve a start in several times |  |

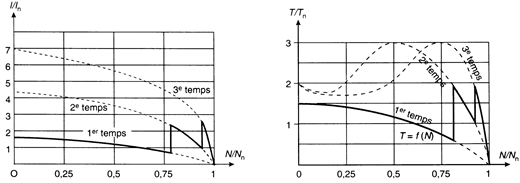

5.2.1. Torque and current curves

In this type of starting, the intensity absorbed by the motor is proportional to the voltage applied to the motor. On the other hand, the motor torque is proportional to the square root of the voltage applied to the motor. |  |

5.2.2. Wiring diagrams

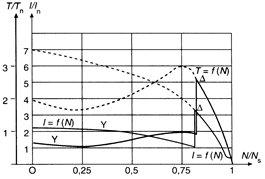

5.3. Start by elimination of rotors resistors

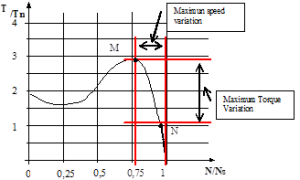

5.4. Variation of the opposite torque by the load

For correct motor operation, the torque opposite the load must not exceed the point M because it causes the machine to stop by "unhooking" of the rotor on the stator. For a zero resistance torque, the speed of rotation of the motor is close to the speed of synchronism (

This gives the maximum variation of the speed as a function of the load. |  |